Custom-made templates in Malaga

Sports podiatry

The acronyms CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) are synonymous with state-of-the-art technology today. We have been working with this system for about 10 years at Clínica del Pie La Malagueta with excellent results for our patients.

This latest technology in the manufacture of insoles allows us to adapt the support (insole) with millimetric accuracy while allowing us to make the corrections proposed in the insole more accurately.

The system allows us to produce the plantar support in a simple and fast way for our patient.

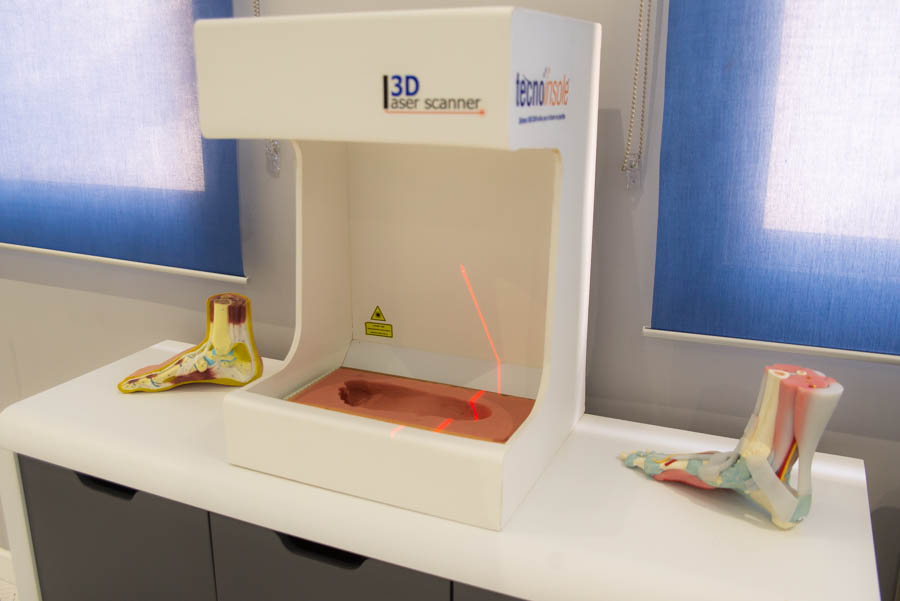

First, we will take a mold of the patient’s foot with Phenolic Foam. Once we have the mold, we will proceed to digitize it using a 3D Laser Scanner to make the appropriate corrections in the CAD system.

The laser sends us the 3D mold of the patient’s foot to the computer and we use the system to make the insole according to the needs of our patient.

A few days later, we received the proposed treatment for our patient in our office.

No, the insoles are a treatment with which we want to compensate for the pathological biomechanics of our patient, therefore, the adaptation process is done progressively, that is, we will use the insoles little by little and we will avoid using them if we practice a demanding activity. At first, we will gradually incorporate it into our activity, until the first check-up in consultation after 3 weeks, at that meeting and after communicating the sensations to the podiatrist we will decide its use.

The insoles are indicated to improve our quality of life not to increase our discomfort, logically at the beginning it is a strange element in the foot, so sure we will notice a different sensations, but in a few days and with a progressive adaptation we will not have problems. In the event of any further problems, we will always be at your disposal to check the templates.

Once we deliver the templates we like to establish a cycle of reviews for the first year, completely free, at 21 days, 3 months, 6 months and one year.

The body of the insole (active part) has a long durability since the materials are of a very high quality, although it is still recommended to change the linings every 12 or 18 months (passive part of the insole).

The hardness of the insole will depend directly on the objective to be achieved with the treatment, patient activity, pathology, age…

The materials used are very diverse today, for us the most used are Polypropylene, carbon fiber, fiberglass and EVA.

If you have any questions about our services or need more information do not hesitate to contact us, we will respond as soon as possible.

We listen to you and look for the best solution for your case.